The future trend of blow molding machine industry

3 min read

The Future Trend of the Blow Molding Machine Industry

The blow molding machine industry has made significant advancements in recent years, driven by technological innovations and the increasing demand for plastic products. As we look towards the future, it is evident that this industry will continue to experience rapid growth and development. In this article, we will explore the key trends that are shaping the future of the blow molding machine industry.

1. Advanced Automation and Robotics

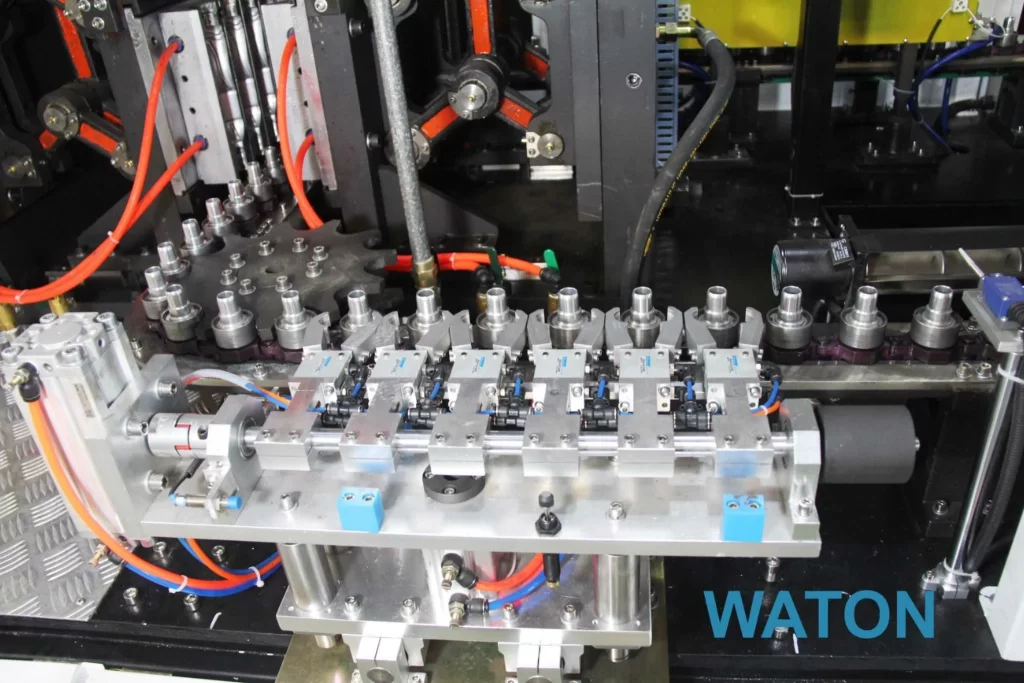

One of the key trends in the blow molding machine industry is the increasing adoption of advanced automation and robotics. Manufacturers are constantly looking for ways to improve productivity and efficiency, and automation plays a vital role in achieving these goals. By integrating advanced robotics into the blow molding process, manufacturers can reduce manual labor requirements, increase production speed, and improve product quality.

Automated blow molding machines can perform tasks such as mold loading and unloading, parison programming, and product handling with precision and consistency. This not only reduces production costs but also minimizes the risk of human error. Additionally, automation enables manufacturers to easily adapt to changing market demands by quickly reconfiguring production lines and implementing new designs.

2. Sustainability and Environmental Considerations

In recent years, there has been a growing emphasis on sustainability and environmental considerations in the manufacturing industry. The blow molding machine industry is no exception to this trend. Manufacturers are increasingly focusing on developing more eco-friendly and sustainable solutions to meet consumer expectations and regulatory requirements.

One area where significant progress has been made is in the development of biodegradable and recyclable materials for blow molding. These materials offer comparable performance to traditional plastics but have lower environmental impacts. Additionally, manufacturers are exploring ways to optimize energy consumption during the blow molding process by utilizing advanced heating and cooling technologies.

Furthermore, waste reduction and recycling initiatives are becoming more prevalent in the blow molding machine industry. Manufacturers are investing in advanced recycling technologies that can process post-consumer and post-industrial waste and convert them into new raw materials. This not only reduces the environmental footprint but also contributes to the circular economy.

3. Industry 4.0 and Digitalization

The blow molding machine industry is embracing the concept of Industry 4.0 and digitalization to enhance productivity, efficiency, and flexibility. Digital technologies such as the Internet of Things (IoT), artificial intelligence, and big data analytics are being integrated into blow molding machines to enable real-time monitoring, predictive maintenance, and process optimization.

By collecting and analyzing data from sensors and connected devices, manufacturers can gain insights into the performance of their machines and make data-driven decisions to improve efficiency and quality. Predictive maintenance algorithms can detect potential issues before they cause equipment failure, reducing downtime and maintenance costs.

Furthermore, digitalization enables manufacturers to implement remote monitoring and control systems, allowing them to manage and optimize production processes from anywhere in the world. This level of connectivity and flexibility enhances overall operational efficiency, reduces lead times, and enables manufacturers to respond quickly to customer demands.

The future of the blow molding machine industry looks promising, with advancements in automation, sustainability, and digitalization driving its growth and development. As the demand for plastic products continues to increase, manufacturers are under pressure to improve efficiency, reduce costs, and minimize environmental impacts. By embracing these key trends and incorporating them into their operations, blow molding machine manufacturers can stay competitive and meet the evolving needs of consumers and the market.

.webp)