Unraveling the Secrets of Blow Molding Technology

Unraveling the Secrets of Blow Molding Technology

Blow molding technology has revolutionized the manufacturing industry, providing efficient and cost-effective solutions for producing plastic products. This innovative process involves the creation of hollow plastic parts by inflating a heated plastic tube called a parison. Understanding the secrets behind blow molding technology is essential for manufacturers looking to optimize their production processes. In this article, we will delve into the intricacies of blow molding and explore its various applications.

Blow molding can be categorized into three main types: extrusion blow molding, injection blow molding, and stretch blow molding. Each method has its unique advantages and is suitable for different product designs and production volumes.

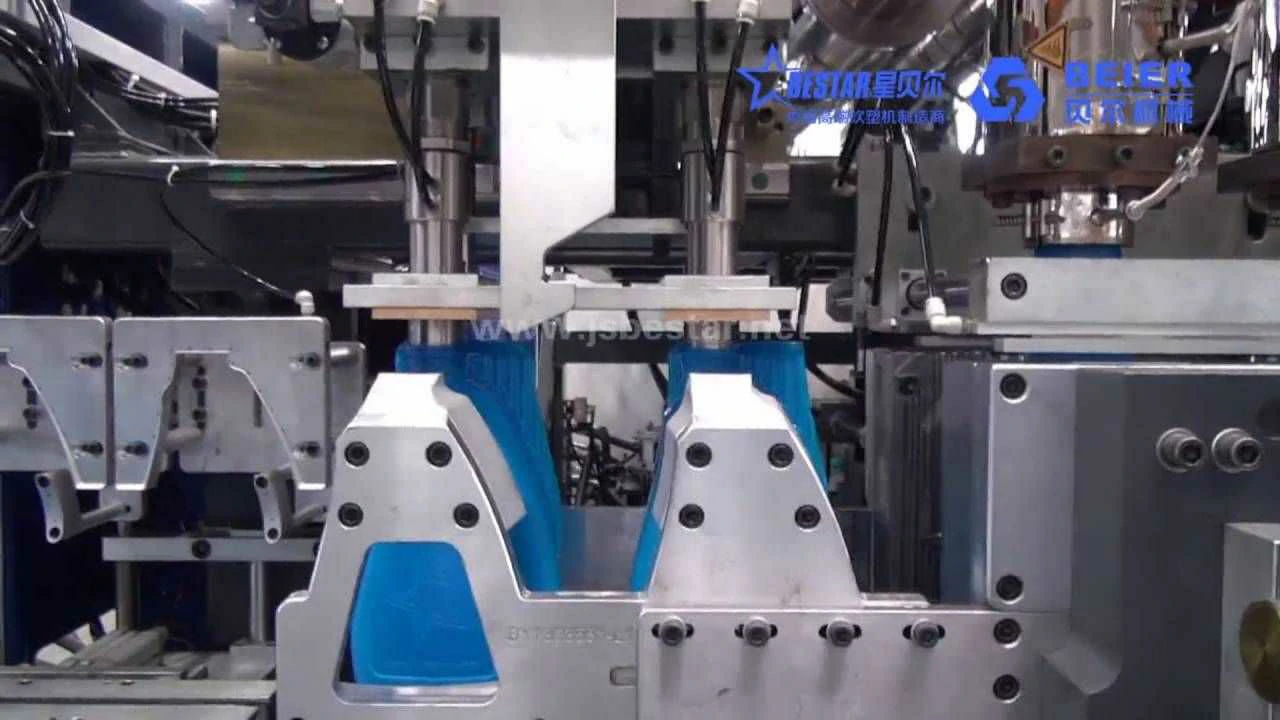

Extrusion blow molding is the most common technique used for manufacturing plastic bottles, containers, and other hollow objects. The process begins with melting plastic resin, typically high-density polyethylene (HDPE), and extruding it into a hollow tube known as a parison. The parison is then transferred to a mold, where compressed air is blown into it, forming the desired shape. This method allows for high-volume production and is highly versatile in terms of design capabilities.

Injection blow molding, on the other hand, is primarily used for producing small, intricate plastic products such as medical devices and pharmaceutical containers. The process starts with injecting molten plastic into a mold cavity, creating a preform. The preform is then transferred to a separate blow mold, where compressed air is introduced to expand and shape the plastic into its final form. Injection blow molding offers precise control over dimensions and excellent surface finish, making it ideal for products that require strict quality standards.

Stretch blow molding combines elements of both extrusion and injection blow molding. It is commonly used for manufacturing PET bottles and jars. The process begins with the injection of molten plastic into a preform mold, creating a partially formed bottle. The preform is then transferred to a stretch blow mold, where it is reheated and stretched in both axial and radial directions using compressed air. This stretching process enhances the material’s molecular orientation, resulting in a stronger and more durable final product.

Blow molding technology offers numerous advantages over other manufacturing processes. It is a highly efficient method that allows for fast production cycles and minimal material wastage. Additionally, blow molded products have excellent strength-to-weight ratios, making them ideal for various applications. The ability to produce complex shapes and intricate designs further expands the possibilities of blow molding technology.

The automotive industry extensively utilizes blow molding for producing components such as fuel tanks, air ducts, and intake manifolds. The lightweight nature and design flexibility of blow molded parts contribute to improved fuel efficiency and overall vehicle performance.

In the packaging industry, blow molding plays a crucial role in the production of bottles, containers, and packaging solutions. The ability to manufacture custom-shaped bottles with precise neck finishes and tamper-evident features has made blow molding the preferred choice for beverage and personal care product manufacturers.

Blow molding also finds applications in the medical field, where the production of sterile and hygienic products is paramount. Medical devices such as inhalers, syringes, and IV bags are often manufactured using blow molding technology due to its ability to produce seamless and leak-proof hollow components.

As with any manufacturing process, quality control is vital in blow molding. Advanced techniques such as automated vision systems and robotic inspection help ensure consistent product quality and detect any defects during the production process. Monitoring parameters such as parison temperature, blow pressure, and cooling time are crucial in maintaining dimensional accuracy and product integrity.

In conclusion, blow molding technology has revolutionized the manufacturing industry by providing efficient, cost-effective, and versatile solutions for producing plastic products. The three main types of blow molding – extrusion blow molding, injection blow molding, and stretch blow molding – offer unique advantages and cater to different product requirements. From automotive components to packaging solutions and medical devices, blow molding has permeated various industries, showcasing its versatility and potential. By unraveling the secrets behind blow molding technology, manufacturers can unlock new possibilities and optimize their production processes for greater success in the market.

https://roboticsolutionhub.com/