Basic knowledge of cables-cable outer sheath structure

Basic Knowledge of Cables – Cable Outer Sheath Structure

Cables are an essential component in today’s interconnected world. They play a crucial role in transmitting power and data, enabling communication and connectivity across various industries. Understanding the basic knowledge of cables is vital for anyone working with or using cables. In this article, we will focus on the cable outer sheath structure, which is an integral part of a cable.

The cable outer sheath, also known as the cable jacket, is the protective layer that surrounds the core of the cable. Its primary function is to provide mechanical protection to the underlying components and to safeguard the cable against environmental factors such as moisture, chemicals, temperature variations, and physical damage. The outer sheath also aids in maintaining the integrity of the cable’s electrical insulation.

When it comes to cable outer sheath structure, there are different types to consider. Let’s explore some common ones:

1. PVC (Polyvinyl Chloride) Sheath: PVC is one of the most widely used materials for cable sheathing. It offers excellent resistance to moisture, abrasion, and fire. PVC sheaths are flexible, making installation and handling easier. However, PVC is not suitable for outdoor applications where exposure to ultraviolet (UV) radiation is a concern, as it can deteriorate under prolonged sun exposure.

2. PE (Polyethylene) Sheath: PE is another popular material used for cable outer sheathing. It provides good resistance to moisture, chemicals, and UV radiation. PE sheaths are commonly used in outdoor and underground installations. They offer high durability and long-term performance under harsh environmental conditions.

3. LSZH (Low Smoke Zero Halogen) Sheath: LSZH cables are designed to minimize the release of toxic and corrosive gases during combustion. The sheath material used in LSZH cables is made of compounds that do not contain halogens. This makes them suitable for applications where safety and low toxicity are critical, such as in public buildings, transportation systems, and data centers.

4. EPR (Ethylene Propylene Rubber) or CSP (Chlorosulfonated Polyethylene) Sheath: These materials are commonly used in medium to high voltage power cables. They offer excellent resistance to heat, chemicals, and weather conditions. EPR and CSP sheaths provide superior protection against moisture and abrasion.

In addition to the material used for the outer sheath, its structure can vary depending on the specific cable application. Some cables may have multiple layers of sheathing, each serving a different purpose. For example, a cable designed for direct burial in the ground may have an inner polyethylene sheath for moisture resistance and an outer PVC sheath for mechanical protection.

Furthermore, the cable outer sheath can be smooth or corrugated. Corrugated sheaths are often used in underground or underwater applications, as the corrugations provide added mechanical strength and flexibility to withstand external pressures.

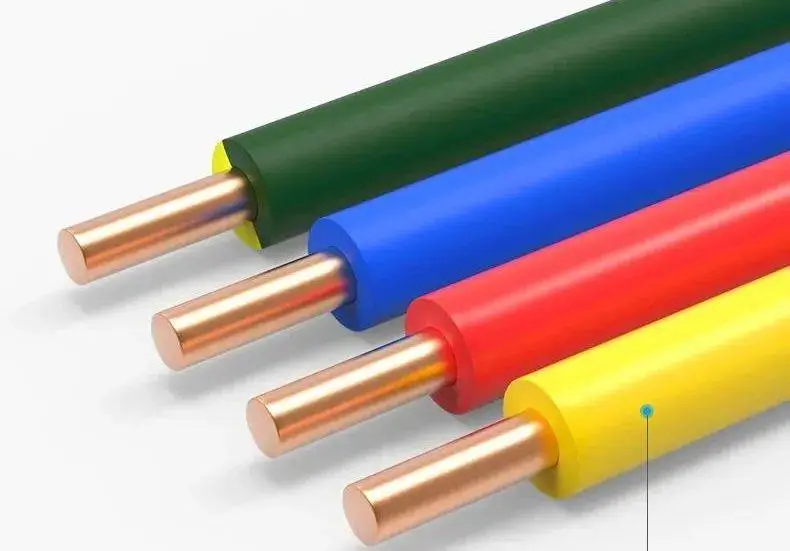

It is important to note that cable outer sheaths are available in various colors, allowing for easy identification and differentiation of cables during installation and maintenance processes.

In conclusion, understanding the basic knowledge of cable outer sheath structures is essential for anyone working with cables. Different materials and structures offer varying levels of protection against environmental factors, and selecting the appropriate type of sheath is crucial for ensuring the cable’s performance and longevity. Whether it is PVC, PE, LSZH, EPR, or CSP, each material has its own advantages and is suitable for specific applications. By considering the cable’s environment and requirements, one can make informed decisions regarding cable selection and installation.